To cite this article: Gilberth Prosper Temba, Ernest William Mauya & George Ansigar Migunga

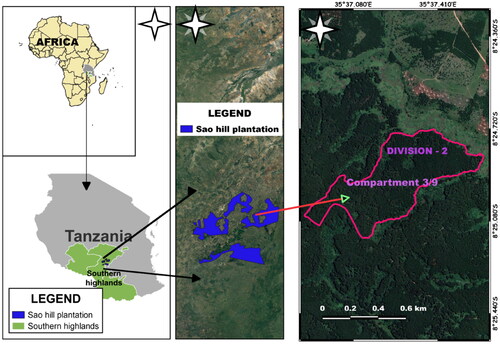

(28 Dec 2023): Productivity and Costs of Mechanized Skidding operations at Sao Hill Forest

Plantation, Tanzania, Forest Science and Technology, DOI: 10.1080/21580103.2023.2299260

To link to this article: https://doi.org/10.1080/21580103.2023.2299260

Due to global advancement of technology in forest operations, utilization of advanced machineries such as grapple skidder (GS) in timber harvesting has been increasing in the last decades. However, in order to understand their contribution in sustainable harvesting operations, it is important to understand their performance under different operating environment.

Therefore, this study aimed to quantify productivity and cost of mechanised skidding operations at Sao Hill Forest plantation (SHFP). Six variables; diameter at a breast height (dbh), tree height, skidding distance, slope, costs, and cycle time (determined using detailed continuous time study) were collected in 120 GS observations.GS productivity and costs were estimated using productive machine hour (PMH) and delays inclusion approach.

Regression models were developed using a generalized linear model (GLM) approach. GS productivity under PMH was 2.6% higher than the one including delay time, while skidding costs was 2.1% higher in the approach including delays. This study revealed significant variations (p-value <0.05) in productivity and cost on various terrain classes. At 0 m – 50 m distance, an average delays free GS productivity was 85.5 m3/h, with costs amounting to 1.7USD/m3

CLICK HERE TO LEARN MORE